Our offer

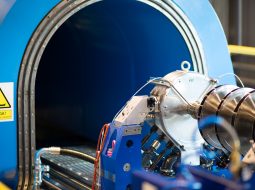

We produce rotating parts for compressors, turbines and industrial pumps including impellers, blades for all the parts of steam turbines and also parts of stators. We also perform extensive modernisation of machineries in order to regain or improve their performance (retrofit, revamp) in framework of which we deliver complete rotors. In addition, we implement modern technologies in terms of sealings, bearings, measuring , anti-surge or governing system. Since 2014 we have owned a stand for high-speed balancing and overspeed testing of rotors and impellers.

Our machine park

-

Measuring laboratory

We possess well-equipped measurement facilities for reverse engineering .Apart from traditional tools, we are also equipped with state-of art optical metrology systems (non-contact measurement of geometrical dimensions), measuring microscope, coordinate measuring machines (measurement accuracy – 1.7um) We also possess stress testing machine for materials physical properties checks. We are able to prepare reconstructive documentation of any elements at the request of the customer without insight into original drawings. We encourage you to familiarize with our offer.

Read more -

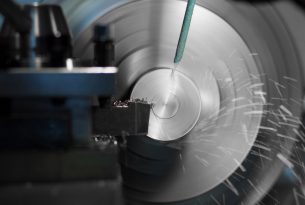

Machining capacities

To provide our clients with high quality of our products we use modern CNC machining centres supported by precise measuring systems as well as tools for reverse engineering. Manufactured components are made with the use of the most modern technologies such as BLISK, electron beam welding or vacuum brazing with the use of noble metals. Please find some information below. We encourage you to familiarize with our offer.

Read more