Engineering services

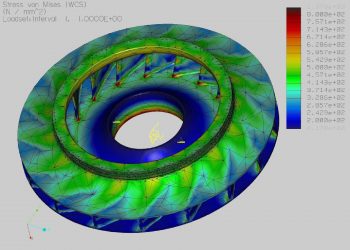

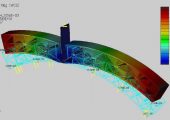

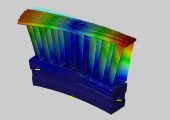

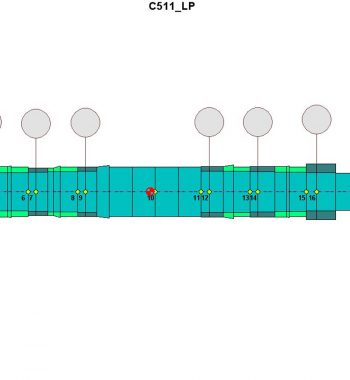

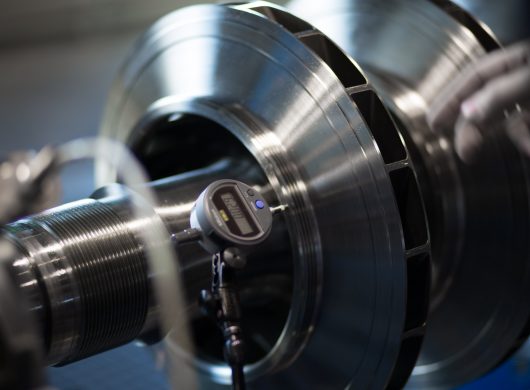

We offer a wide range of professional engineering services – stress analysis, dynamic and aerodynamic calculations for fluid-flow machines as well as their components. Reverse engineering and precise measurements of components with the use of the most modern measuring machines.