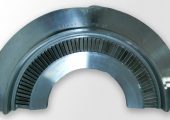

PRODUCTION OF SPARE PARTS

Production of energy-related components dedicated for fluid-flow machines. We offer manufacturing of complete rotors, single shafts, impellers, discs with blades and blade shrouds in accordance with documentation provided by a client. We also possess reverse engineering facilities – in case of lack of documentation, it is possible to reconstruct the particular model thanks to the existing element.