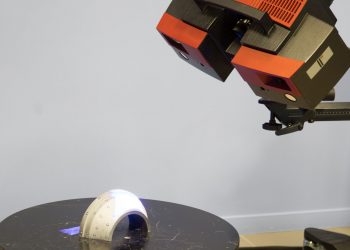

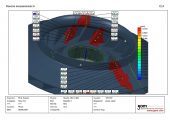

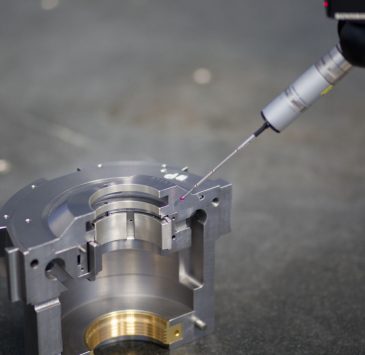

Measuring laboratory

We possess well-equipped measurement facilities for reverse engineering .Apart from traditional tools, we are also equipped with state-of art optical metrology systems (non-contact measurement of geometrical dimensions), measuring microscope, coordinate measuring machines (measurement accuracy – 1.7um) We also possess stress testing machine for materials physical properties checks. We are able to prepare reconstructive documentation of any elements at the request of the customer without insight into original drawings. We encourage you to familiarize with our offer.